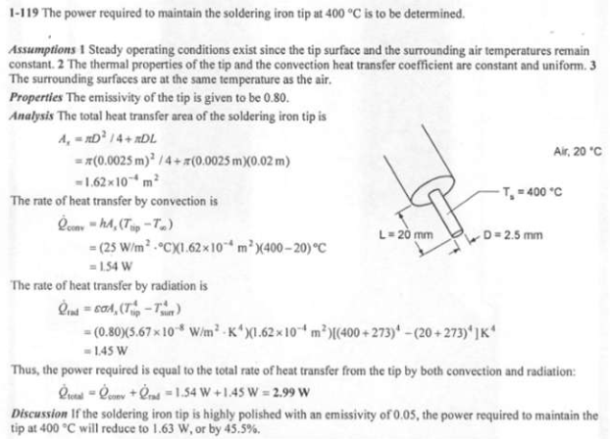

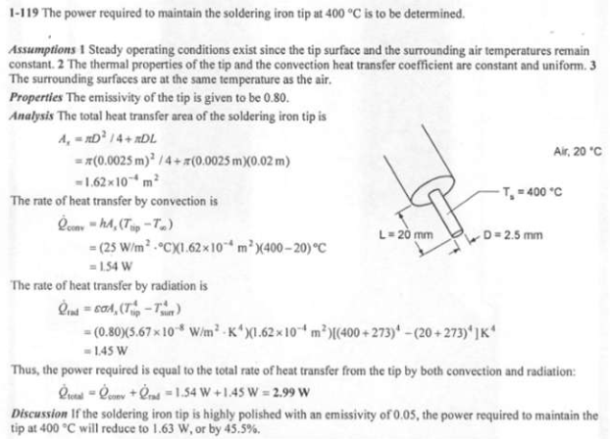

A soldering iron has a cylindrical tip of 2.5 mm in diameter and 20 mm in length. With age and usage, the tip has oxidized and has an emissivity of 0.80. Assuming that the average convection heat transfer coefficient over the soldering iron tip is 25 W/m^2K, and the surrounding air temperature is 20 C, determine the power required to maintain the tip at 400 C.

A soldering iron has a cylindrical tip of 2.5 mm in diameter and 20 mm in length. With age and usage, the tip has oxidized and has an emissivity of 0.80. Assuming that the average convection heat transfer coefficient over the soldering iron tip is 25 W/m^2K, and the surrounding air temperature is 20 C, determine the power required to maintain the tip at 400 C.